How 3D Printing Is Transforming Organ Transplants

Scarlett Brooks

2025-10-30

6 min read

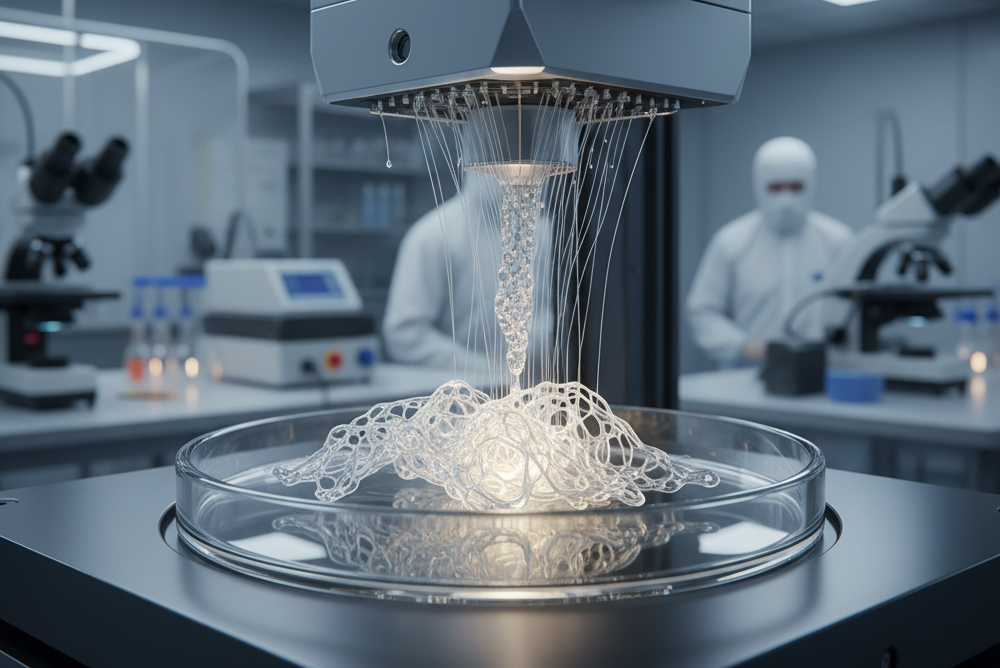

For decades, organ transplantation has been a modern medical miracle, offering a second chance at life to patients with failing organs. Yet, this life-saving procedure has always been constrained by a critical challenge: the severe shortage of donor organs. Every day, patients wait anxiously for a match that may never come. Now, a groundbreaking technology is emerging from the world of advanced manufacturing that promises to revolutionize transplantation and potentially solve the organ shortage crisis: 3D printing. This advanced form of additive manufacturing, also known as bioprinting when used with biological materials, is moving from science fiction to scientific reality. It offers the potential to create custom-made, fully functional organs on demand, transforming the future of regenerative medicine and offering new hope to millions.

Addressing the Organ Shortage Crisis

The fundamental problem with traditional organ transplantation is supply and demand. The number of patients in need of hearts, kidneys, livers, and lungs far exceeds the number of available donor organs. This gap leads to long, uncertain waiting lists and, tragically, many patients die before a suitable organ becomes available. 3D bioprinting directly addresses this issue by offering a method to manufacture organs from the ground up. The process typically involves using a patient's own cells, which are cultivated in a lab and then formulated into a "bio-ink." A specialized 3D printer then deposits this bio-ink layer by layer, following a precise digital blueprint derived from the patient's medical scans. This method allows for the creation of a scaffold and the placement of cells with incredible accuracy, gradually building a complex, three-dimensional biological structure. While printing a fully functional, complex organ like a heart or liver is still a long-term goal, researchers have made remarkable progress. Simpler tissues and structures, such as skin, cartilage, and blood vessels, have already been successfully printed and tested. These early successes provide the foundational knowledge needed to tackle more complex organs, bringing the possibility of on-demand organ creation closer to reality.

Reducing Rejection and Improving Patient Outcomes

Beyond solving the supply issue, 3D printing offers another profound advantage: minimizing the risk of organ rejection. When a patient receives a donor organ, their immune system often recognizes it as a foreign object and launches an attack. To prevent this, transplant recipients must take powerful immunosuppressant drugs for the rest of their lives. These medications carry their own significant health risks, including an increased chance of infection, kidney problems, and cancer. Bioprinting circumvents this problem by using the patient's own cells as the building blocks for the new organ. Since the printed organ is made from the recipient's genetic material, the body's immune system recognizes it as "self." This autologous approach drastically reduces, or could even eliminate, the risk of rejection. Patients would no longer need to rely on a lifetime of immunosuppressants, leading to better long-term health outcomes and an improved quality of life. Furthermore, 3D printing allows for unprecedented customization. Each printed organ can be perfectly tailored to the recipient's body. Using detailed MRI or CT scans, doctors can create a digital model that matches the patient's specific anatomy in size and shape. This precise fit improves surgical outcomes and ensures the new organ functions optimally within the body.

The Stepping Stones to Full Organ Printing

The journey toward printing complex organs is being built on a series of incredible achievements with simpler structures. Scientists have successfully printed and implanted tissues like bone, cartilage for reconstructive surgery, and patches of skin for burn victims. These applications serve as crucial stepping stones, allowing researchers to refine the techniques for vascularization—the process of creating the intricate network of blood vessels necessary to supply an organ with nutrients and oxygen. Vascularization remains one of the greatest challenges in bioprinting. A solid organ like a kidney or liver requires a complex vascular tree to survive. Researchers are experimenting with various techniques, such as using dissolvable materials to print channels that later become blood vessels or encouraging cells to self-assemble into vascular networks. Each breakthrough in this area brings the medical community one step closer to creating viable, transplantable organs. In addition to tissue engineering, 3D printing is already having a major impact on surgery today. Surgeons use 3D-printed replicas of a patient's organs to plan and practice complex procedures before entering the operating room. These models allow them to anticipate challenges and refine their approach, which reduces surgical time, minimizes blood loss, and improves patient safety.

The Road Ahead

While the promise of 3D-printed organs is immense, significant hurdles remain. Ensuring the long-term viability and function of printed tissues, scaling up the manufacturing process, and navigating the complex regulatory approvals are all challenges that must be addressed. However, the pace of innovation in this field is incredibly rapid, with research institutions and biotech companies around the world making consistent progress. 3D printing is poised to shift the paradigm of transplantation from one of replacement to one of regeneration. It represents a future where a patient's own cells can be used to create a perfect, rejection-proof organ, ending the agonizing wait for a donor and transforming the treatment of organ failure. This convergence of biology, engineering, and medicine is not just an incremental improvement; it is a revolutionary leap that holds the key to a healthier future for countless individuals.